Gd T On Assembly Drawings

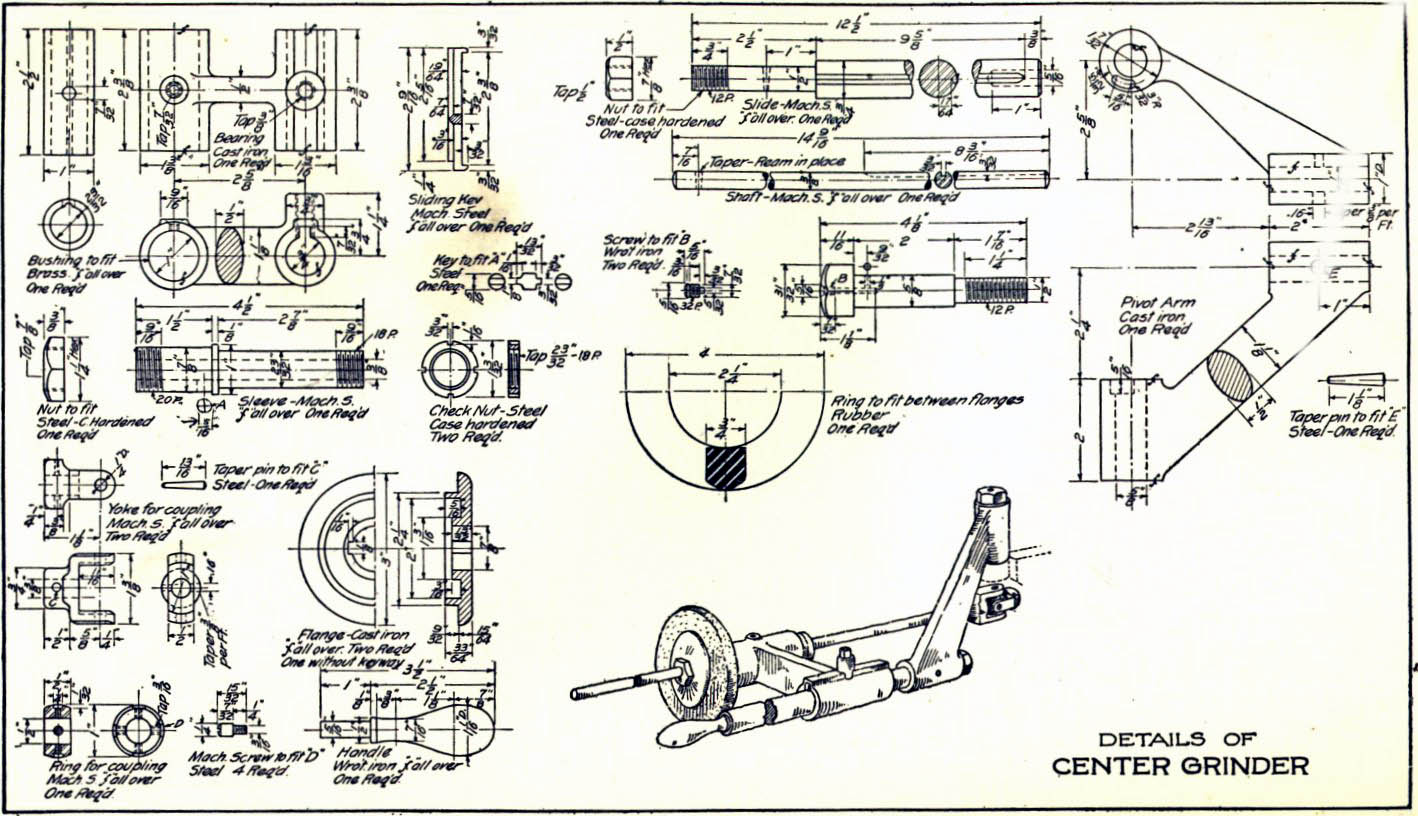

If a part is drawn with the proper dimensional controls gd t to assure its assembly with the other parts and the part.

Gd t on assembly drawings. Tolerances and why do we need them. This will allow you to understand the intent of the product designer which will allow you to assess the conformance of a unit coming off of your production line. Of a surface tolerance there is the option of specifying that the tolerance applies all over on the field of the drawing. Therefore the ten associated symbols are the most utilized of the fourteen total gd t symbols.

The tec ease gd t glossary and free resource features explainations of gd t terms and symbols. Consider the below figure. If there are differences how can you differentiate between the drawings for these. Since variation from the drawing is inevitable the acceptable degree of variation must be specified.

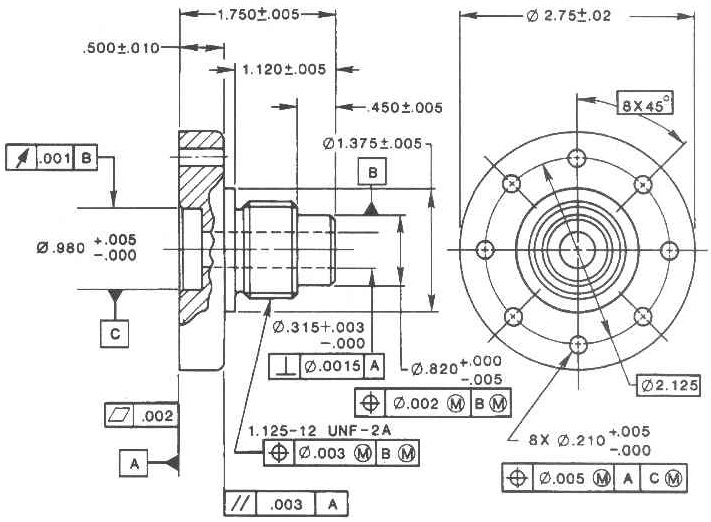

I also wondered if somebody can share a very well constructed drawing of a sheet metal component with 1. Gd t for assembly 2. Gd t tells manufacturing partners and inspectors the allowable variation within the product assembly and standardizes how that variation is measured. As a quality engineer you will be expected to be able to read and interpret engineering drawings and the gd t associated with that drawing.

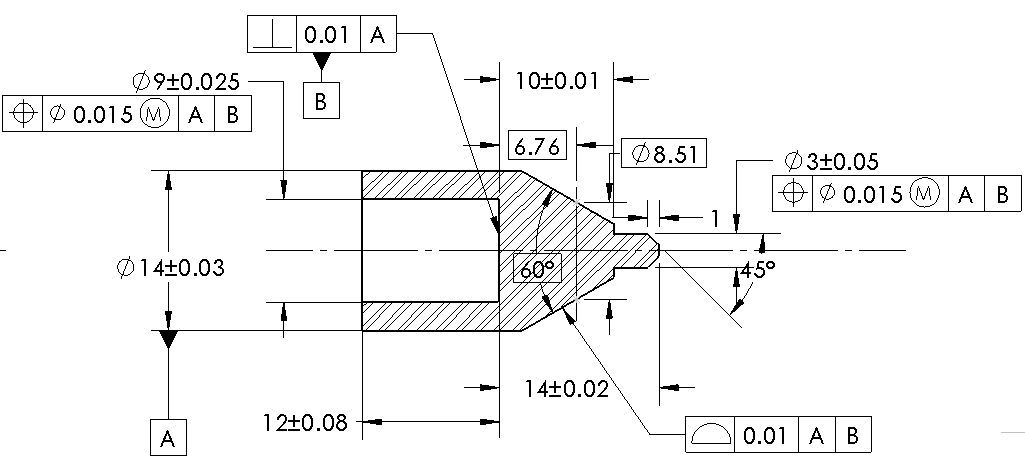

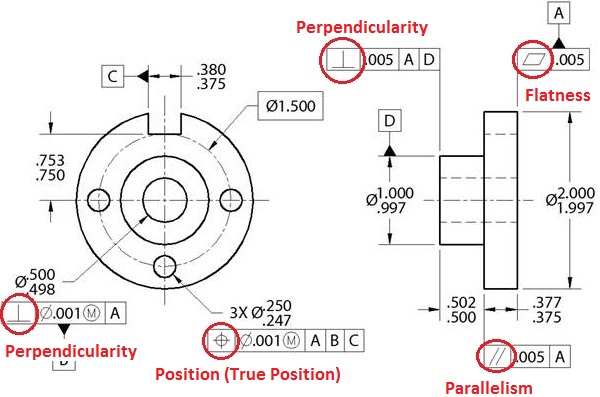

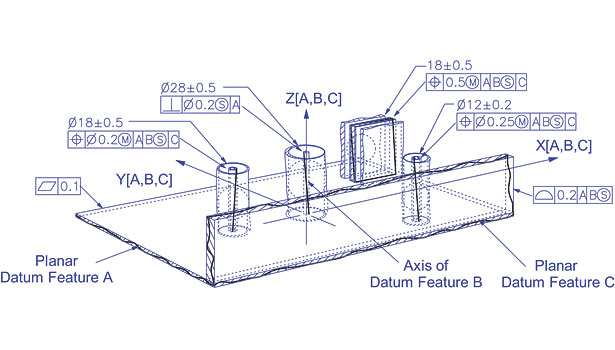

The most frequently used tolerance categories are form orientation and location. Gd t and the quality engineer. Creates a zone defined by two arcs the minimum. Geometric tolerances are applied to features by feature control frames.

To optimally control and communicate these variations engineers and manufacturers use a symbolic language called gd t short for geometric dimensioning and tolerancing. Considering the figure below it can be interpreted in two ways. Now without gd t this drawing is supplied to production department. Different types of tolerances.

Gd t for manufacturing and 3. As you know that angle is equal to chord divided by radius. So variation from theoretical value exceed greatly as dimension. Tolerancing gd t mem 201.

All engineering industries benefit from using gd t to more clearly define their drawings and eliminate the limitations with a basic coordinate based system. An important functional profile like a cam follower and 2. Department of mechanical engineering and mechanics today s objectives. Consider the note says all the angle should be within 1.

Gd t is applied to the drawings of parts as they are designed theoretically to insure they will always fit during assembly. As an automotive engineer designing with gd t is an industry standard to clearly describe how a unit is to be manufactured so that it fits within the top level assembly. And screw relative to its assembly with the mating part.